Though Tim King’s day-job involves engineering responsibility for over 2000 lorries but discharged from behind a desk, his real passion is hands-on restoration. Peter Simpson takes a look at the fine Volvo F86 restoration that took ten years to restore.

Back in 1982, a fresh-faced 16-year-old Tim King joined local haulage firm A A Griggs of Soham as an engineering apprentice. Founded in the mid-1930s by the late Alfred Griggs, the firm Tim joined had started out as a pretty typical fenland haulage business, with local produce as its main traffic. When Tim joined, the business was still family-owned. It had, however, passed to the second generation, in the shape of Alfred’s son Tony.

The main customer-base had changed too. By 1982 the Griggs fleet spent most of their time working in the papermaking and packaging industry. By the time that Tim left in 2001, (to become Group Fleet Engineer at Turners (Soham) Ltd.,) the Griggs business had been acquired by David S Smith a large papermaking business. Known today as D S Smith, this business is now employs 30,000 people in 30 countries worldwide.

Changing times

The 1980s was also, of course, a time of significant change within the road haulage industry, and Griggs was no exception. “When I joined, the fleet was mainly Volvo, but still running Ford D-Series, Bedford TKs and a few Leylands, Tim told me. By the time Tim left, however, the 200-strong Griggs fleet was nearly 100% Volvo – principally FL10s and FM12s.

Though owned by the Smith Group, Griggs was still being operated as a separate road haulage business. Some work away from the paper industry was still undertaken. This included a contract with the United States Air Force to move equipment to and from the USAF bases at Lakenheath and Mildenhall. On occasion Griggs also took stores and supplies from here to US Navy ships operating around Europe. Sometimes, Tim’s late father Roger, drove for Griggs on these overseas runs.

Genuine Griggs Volvo F86

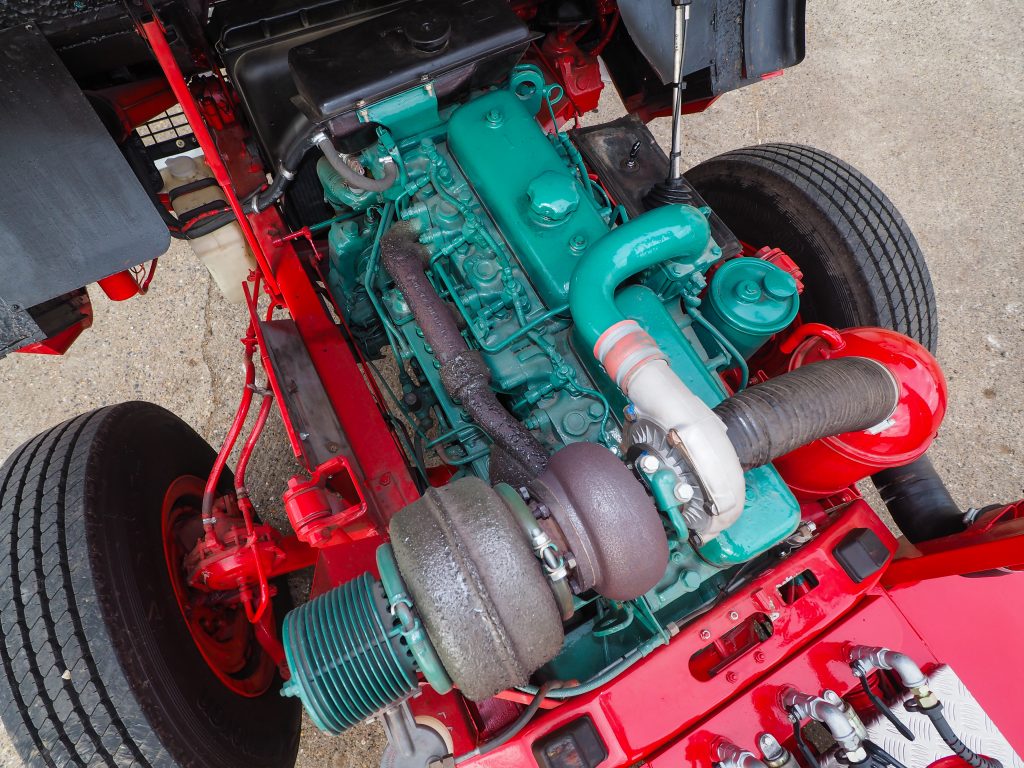

Volvo F86 tractor unit SVE369S is a genuine ex-Griggs lorry, supplied new to them by JF Duffield & Son on May 1 1978. The specification included a Volvo TD70E engine and R5 gearbox, both of which it retains. After its frontline service ended it was retained as a yard shunter.

From here, the Volvo F86 eventually passed to Tony Griggs’ son Simon, who was setting up his own haulage company based in March, Cambridgeshire. Here too it was used as a shunter until pensioned off. Then, still owned by Simon, it was parked up in R J Flack’s yard near March.

Tim, meanwhile, though settling into his new role at Turners, remained on very good terms with the Griggs family. He had also become involved with commercial vehicle preservation. In 1996 he completed the full restoration of an extremely rare 1951 Scheuerle rear-steer heavy haulage trailer his Dad had used extensively. To go with this, he had also bought and renovated a 1976 Volvo F88 tractor unit.

Unsurprisingly, he also had his eye on the former Griggs Volvo F86. As often happens, though, at first Simon Griggs was reluctant to sell. Tim persisted however. Eventually Simon agreed to let him have the lorry on condition Tim restored in its original Griggs colours. As this was what Tim wanted to do anyway, he agreed, and took possession in 2007. As Simon has only used the Volvo F86’s off-road, it had never been registered in his name. Tim is therefore only the second registered keeper, the first being A A Griggs and Co.

Two year delay

Tim couldn’t, however start the restoration for another two years, as the cab was rusted beyond realistic repair, and it took that long to find a replacement. Eventually, they found one Klazienaveen, Holland. Tim, accompanied by his Dad, took the F88 and Scheuerle tractor/trailer combination across to Holland to collect it. While there they called in on the Truckstar show in Utrecht.

Tim began work with dismantling the F86 down to the main chassis rails and axles. He then shot-blasted these to remove lots of surface corrosion, followed by priming and painting. Most of the original metal air and fuel pipelines were in good order, though Tim renewed the rubber sections, along with all the chassis wiring. He also made, from scratch, a new fifth wheel subframe as the original had rusted beyond repair. He also made new original-pattern run-up ramps.

Tim overhauled the brakes with new linings and chambers all round and cleaned up the drums for re-use. He stripped, servied and re-assembled the suspension and steering and fitted new steering joint rubber boots. Tim also made a new battery box – again from scratch – and carried out a few localised repairs to a secondhand replacement fuel tank. The Volvo F86 has four air tanks. Three were reused but one had to be renewed. Finally on the rolling chassis side, Tim fitted new tyres all round.

The engine needed a “good service and tappet adjustment” and a new clutch, but the gearbox needed fresh new oil. Tim cleaned both units thoroughly on the outside before repainting them in the original Volvo lime green. Since the F86 returned to the road it has needed a new water pump. This is not uncommon when a vehicle is put back into use after a long period of idleness.

Cab renovation

According to Tim, the hardest part of the whole restoration was refurbishing and adapting the replacement cab. Though he bought it from an enthusiast in Holland, the ‘new’ cab came from Sweden, having been on an aircraft refueller at Arlanda Airport. Though in good condition overall, it did need a few localised repairs.

The biggest problem, though, was that it was a left-hand-drive cab. These have different floorpan assemblies, so Tm had to swap amd reuse the floor from the original cab. This is quite an involved job as the rest of the cab has to line up with the floor. But to make matters even worse, in this case there was an additional problem in that the old cab’s floor had extensive corrosion around the driver’s footwell. Needless to say repairing this, and then making it all fit, took quite a bit of time and patience! New front wings were made by Sheffield-based Frank Newell.

Much of what we see now inside the superbly-restored cab is the original material refurbished. This includes the instruments, tachograph and even the carpet over the engine cover. Tim repainted the dash and other interior metalwork and while the seats and the rear shelf/bunk retain their original frames trim specialist P M Taylor of Burwell made nrew cover.

Old loom, new loom

The cab wiring loom is also the original with a few repairs/renewals as required. Joining this to the new loom within the chassis was quite straightforward, as there are only seven wires to join which run to the rear of the chassis. The rear lights on the chassis, incidentally, are the same as those used on Volvo BM dumptrucks, so readily available.

The project was finally finished at the end of 2019. Unfortunately, Tim did not get any shows under his belt before Covid struck, with the first showing being in May 2021. All in all, this project took ten years to complete, and Tim did pretty-much everything himself. He wasn’t, though, in any hurry; rebuilding his own lorry was his Saturday Morning hobby.

Tim is keen to thanks to Alan and John at A & N J Turner for allowing him to use their premises to restore the lorry. Apart from the things we’ve already mentioned, the only things he didn’t do himself was painting the cab which he managed to persuade a one of the Turners painters to do for him (thank you Tom), and the signwriting, in the original Griggs style from 1978, which was done by Newmarket-based Robin Taylor.

A pleasant respite…

So there we are. Tim freely admits that he enjoys hands-on involvement with fixing lorries, and we’re sure he finds his growing classic collection, and his Saturday morning hands-on restoration sessions, to be an excellent antidote to a high-intensity day job. As Group Fleet Engineer he has overall engineering responsibility for the Turners Soham fleet (plus, since Turners bought a controlling interest in 2019, the Jack Richards fleet, added to other companies which Turners have acquired. Combined, the Turners group have more than 2000 tractors and 3500 trailers, So yes, it’s a high-pressure job. It’s also one which, despite the job-title, involves lots of driving a desk and driving to meetings, and only a little bit of driving lorries.

Needless to say, some other projects are underway and waiting in the wings. At the time of writing he is “half way through” restoring a 1969 York Diamond two-axle trailer which, when finished, will be paired with the F86. Next in line after that is a 1974 Volvo F89 6×4 tractor unit. And when that is finished, he has a 1994 Volvo FL10 which was new to Turners.

So it looks like Tim’s got plenty to occupy those Saturday morning de-stress sessions for a good few years yet…

To read more articles like this every month, subscribe to Classic & Vintage Commercials magazine by subscribing here. And find the latest news, exclusive looks and more at the CVC website here.