I met Alan Robinson, along with friends Fred Webb and Peter Jeffrey at a show in 2024. The trio were displaying an extremely well-restored 1946 Bedford O Type LWB tipper. I was, of course, keen to feature it in the magazine. and, of course, on this website. It was clearly a fabulous rebuild with exemplary attention to detail. They subsequently told me that the restoraruin had taken them 32 years. Yes, you read that right; thirty two years!

First though, we need to talk a bit more about the people behind it. Alan spent his whole working life as a coachbuilder at Papworth Coachworks. Fred Webb has been involved in the animal feed/grain businesses for his entire working life. He is joint-owner of ‘The Country Store.’ This is a gun shop, animal and pet feeds and country clothing business in Pampisford, Cambridge. Alan and Fred have been friends since childhood.

The third member of the team is Peter Jeffrey. Peter became involved ten years into the project when asked to rebuild the engine and fit hardened valve seats. That, though, was 25 years ago. Over the ensuing time he has done much of the mechanical work. He also often takes the Bedford to shows that are a little way away on the back of his classic Foden Alpha and low loader. This means two vehicles can be shown by just one driver and one journey.

The Bedford Fred Found

As a grain trader Fred visited farms around Cambridge regularly. One regular client was Great Abingdon Farm, just outside the city. Here, he was aware that an old lorry had been parked up in a barn for at least 20 years. It had been used in the fields to run alongside a combine harvester collecting grain. Then, on a visit in 1990, he noticed that the lorry, now identifiable as a 1946 Bedford, had been moved outside. Subsequent enquiry elicited that the barn was now needed for other purposes. As for the Bedford, it was going for scrap once its wooden parts had been ripped off and burnt.

Fred and Alan, however, felt that shouldn’t be allowed to happen. In Alan’s words, it was “begging to be restored.” Having spent his entire working life building commercial vehicle bodies, Alan had the skills needed. So the pair went halves and bought it.

Like most lorries acquired in circumstances such as this, the Bedford looked rough. Beneath the surface it was, however, somewhat better than it appeared. All things considered, the barn had protected it pretty well. It was also complete apart from the tailboard. Despite rats having feasted on the wiring loom, with fuel and a battery added, the engine started and ran.

A long project

The project took a full 32 years to complete; bought in 1990, first events attended (and with a few bits and pieces to complete) in 2022. There were several reasons for this. For starters, Alan and Fred both had other things to do, and finishing the Bedford was never their major priority. They also wanted to do a good job.

Finding somewhere to work on the vehicle with decent facilities and security was tricky. In all, the dismantled/part restored lorry had to move three times over the 32 years. On one occasion they vacatied a site after several important parts ‘went missing’ including the radiator and nearside front wing. Eventually, a good and secure long-term home was found with Chris Bates at Gipsy Corner Farm near Little Chisel. The team want to acknowledge Chris’s support; “without him we would never have finished it.”

The lorry was fully dismantled “down to the last nut and bolt” according to Alan. Somewhat surprisingly, the main chassis was solid and didn’t need any welding or renewal. Some Oxy-Acetalyne was, however, used to straighten the rear crossmember which had been bent by use as an improvised towbar. Cleaning the rest of surface rust and repainting it afterwards was, however, somewhat laborious and time-consuming. One spring had a broken leaf which Alan was able to get welded at work. Until his retirement, Alan took individual steel components (smaller than a complete chassis…) into Papworth and have then blasted.

All Imperial

Papworth also assisted the project in another way. While it was underway they switched, overnight, from using imperial fixings and fastenings to metric. As the switch was instant and total, the entire stock of imperial components was to be sent for scrap. Alan was therefore able to help himself to as many imperial nuts, bolts, washers and so on as he wanted. This had three major benefits. Firstly he was able to use new fixings pretty-much everywhere. Secondly they cost nothing. Finally, there isn’t a single metric nut and bolt, or Pozidrive screw anywhere on the entire lorry. Everything is period-correct. Alan was also able to use contacts that supplied Papworth with materials such as wood and sheet metal.

Back with the restoration proper, the cab was remarkably sound in terms of corrosion. It did, however, require one significant repair to the back panel. Here, the rear window had been removed and the surrounding metalwork cut and folded back to enlarge the aperture. The idea was to provide a better view of the combine’s chute while out in the fields.

The original metalwork was, however, all still present having been bent back rather than cut away, so Alan was able to push it back in to shape, weld up the cuts and fit a replacement window. This, along with a replacement for the missing nearside wing and many other parts, came from Norwich-based specialist Chris Morter. The doors too were basically sound, but one of the side engine covers had some localised corrosion. Here, Alan made and welded in a repair section.

Cab needed work

The cab interior needed work. The main issues were that the seat covers had deteriorated beyond repair and the fibreboard headlining was missing. The seats were reclaimed by one of the trim-workers at Papworth who took them apart, blasted, cleaned and painted the seat frames and cleaned up the sprung bases and backs. He then made new covers using material which though not a 100% match for the original, is very close and the best currently available. For the headlining, Alan was able to borrow a set of pressing tools from Andy Usher, who had designed and used them to make a new headlining when he restored his Father Bill’s Bedford O tractor unit. The procedure here is to cut a flat piece of board to shape, wet it, clamp it in the tools, leave it two or three days and then remove the now-shaped headlining.

The lorry came with a ‘farmyard paintjob’ in red applied, possibly, to make it stand out better in fields. Rubbing this down revealed not only the original green, but signwriting from previous owners C H Long of Fornam St Martin, near Bury St Edmunds. Alan has since met up with the grandson of the Bedford’s original owners who has, apparently, requested “first refusal” should the Bedford ever be sold. Peter painted the cab using ICI polyurethane paint and the local ICI representative was able to identify ICI code 383 as the closest to the original. Alan, Fred and Peter have chosen not to reinstate the original signwriting. It is, hwever, now finished in the original colour it is basically as it would have been delivered in 1946.

Bedford Body Rebuild

The main restoration work centred on the tipper body, which of course was Alan’s professional speciality. A new base was made from Keruing, incorporating five new 7ft bearers, along with four 13ft front-rear timbers. The body floor is also new, but all dropside boards apart from the top ones are the originals. The side tops have been trimmed in stainless steel. Alan is aware that this isn’t correct for a working lorry, but it is what was available, and under the paint it’s not noticeable. Alan also made a new tailboard to replace the missing original.

As the photos show, the Edward Brothers tipping mechanism is now fully operational. All it took to achieve this was a new set of ram seals. These came from Allseals of Norwich who, on being asked if he could still supply imperial-sized seals, replied that these were easier to source than metric ones. Despite the old ones being totally worn out and badly mis-shaped, said specialist was also able to identify them and supply a new set by return of post. Once finished, the body was painted by “a workmate” of Alan’s.

Mechanicals

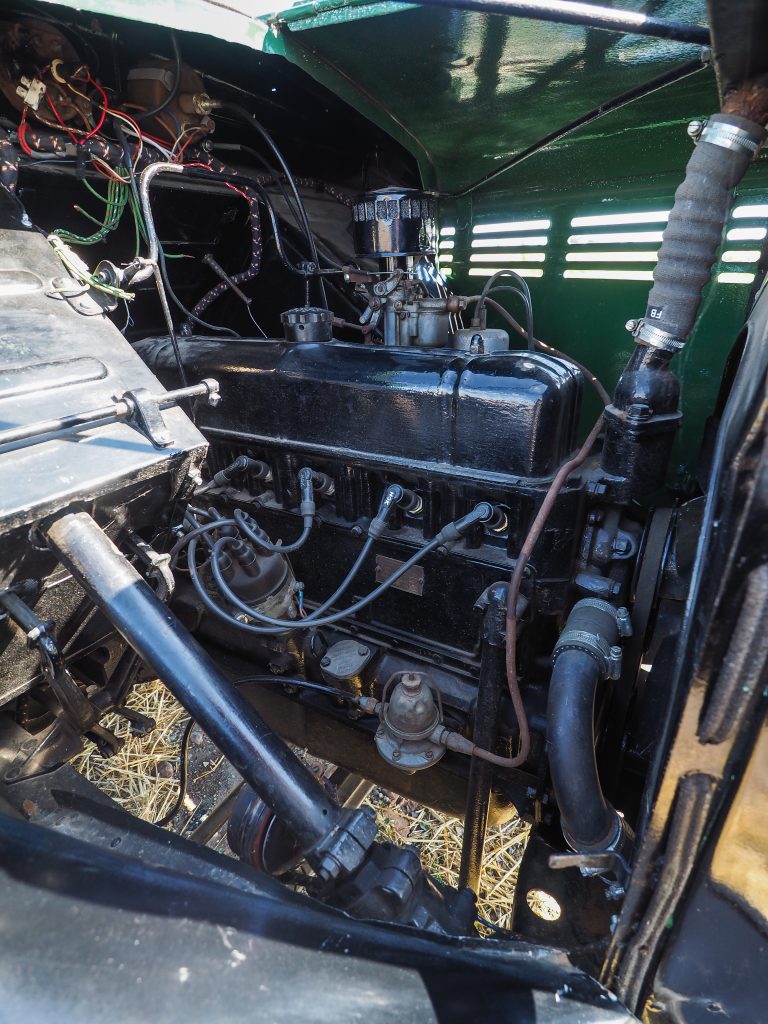

Peter’s main involvement was, as noted previously, on the mechanical side. It started with an engine rebuild and fitment of hardened valve seats. A new clutch was supplied by Chris Morter. No work beyond cleaning and servicing was needed to the engine ancillaries, or to the gearbox or rear axle, though thanks to previous use of a too-long halfshaft bolt, the offside rear wheel bearing was damaged and needed renewing.

When bought, the Bedford had one odd wheel, a replacement for which came from a contact near Kettering. New brake linings were needed along with a replacement master cylinder, but the wheel cylinders could be rebuilt, and the original drums reused.

There was, however, a slight ‘issue’ when it came to the steering box – basically while it was being removed the column parted company with the actual box! Here again Chris Morter came to the rescue with an exchange replacement for £150. Six new tyres came via Abbey Tyres in Cambridge.

Unsurprisingly given the ‘rat issue’ noted earlier, a complete new wiring loom was needed, though there isn’t actually a lot to rewire on a 1946 Bedford! The loom itself came from Chris Morter, and Peter fitted most of it, with some assistance from a couple of auto-electricians.

And with that, the lorry was basically finished; in fact it attended its first shows in 2022 (Stradsett and Kelsall) with the wiring still to be completed. For 2025, its already booked into both these, and a number of other attendances are planned including the Classic & Vintage Commercials show at Gaydon in July.

Registration Problem

There is, however, one issue which Alan, Fred and Peter are still hoping to overcome; that of registration. The Bedford’s original registration was GV6597, a genuine and lovely West Suffolk mark issued by Bury St Edmunds motor taxation office in 1946. But because the Bedford was used exclusively off-road from the early 1970s, it was never Swansea registered, and missed the 1984 deadline for transfer. Consequently, when it came to registering the completed lorry, although the correct number was known, DVLA couldn’t reallocate it without documentary proof.

With help from the Bedford Enthusiast Club, Fred was able to satisfy them that the lorry was made in 1946, and on that basis DVLA issued ‘age related’ registration NXS391. The team would, however, dearly love to have GV6597 back – that’s really as much part of the lorry’s history as its original colour scheme. Great Abingdon Farm did get the original buff log-book when they bought the lorry in around 1970, but of course it can’t now be found! The team are therefore looking at other ways of proving lorry and number belong together; one possibility that’s currently being investigated is that the Bury St Edmunds Local Records Office are thought to hold original registration cards up to 1946.

But meanwhile, if anyone reading this happens to recognise the lorry under that registration or, better still, knows of any photographs or other information linking lorry and number, do please get in touch via the magazine.

To read more articles like this every month, subscribe to Classic & Vintage Commercials magazine by subscribing here. And find the latest news, exclusive looks and more at the CVC website here.